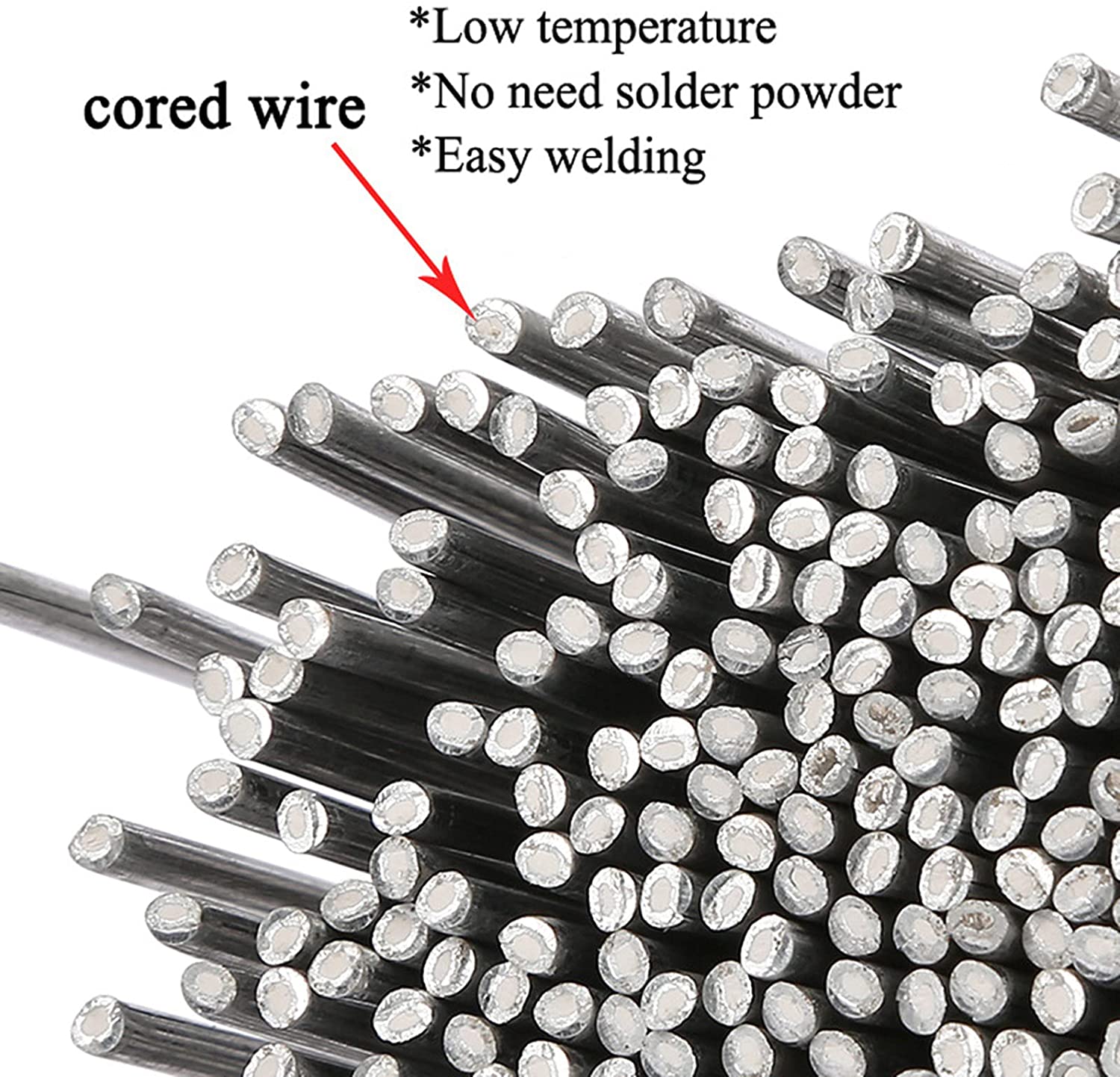

1, production efficiency: for production efficiency, cored wire uses continuous welding, so the production efficiency is high; Compared with solid welding wire, cored welding wire has less spatter and better weld forming, so it reduces the time of spatter removal and weld surface grinding.

2, adaptability to steel: compared with solid wire, cored wire is generally through the core transition alloy elements, so you can easily adjust the alloy composition like manual electrode, to meet the requirements of the welded steel. And solid wire each adjustment of the alloy composition, it is necessary to re smelting, its process, difficult to control, so it is difficult to meet the requirements of less and more varieties. And some alloy steel solid core wire drawing performance is poor, it is difficult to pull into the required wire. Cored wire at this time more obvious its unique advantages.

3, the cost of use: compared with manual electrode and solid wire, the price of cored wire itself is very high. But for large size, after using cored wire, the production cycle is shortened and the weld quality is easy to ensure, so the comprehensive benefit is very high.

www.chingray.com

www.chingray.com

4, moisture resistance: ordinary core wire due to the constraints of its manufacturing form, there is a continuous gap on the side of its steel skin. Therefore, the cored wire can not be used for too long after opening the package to prevent excessive moisture absorption and affect the welding quality.

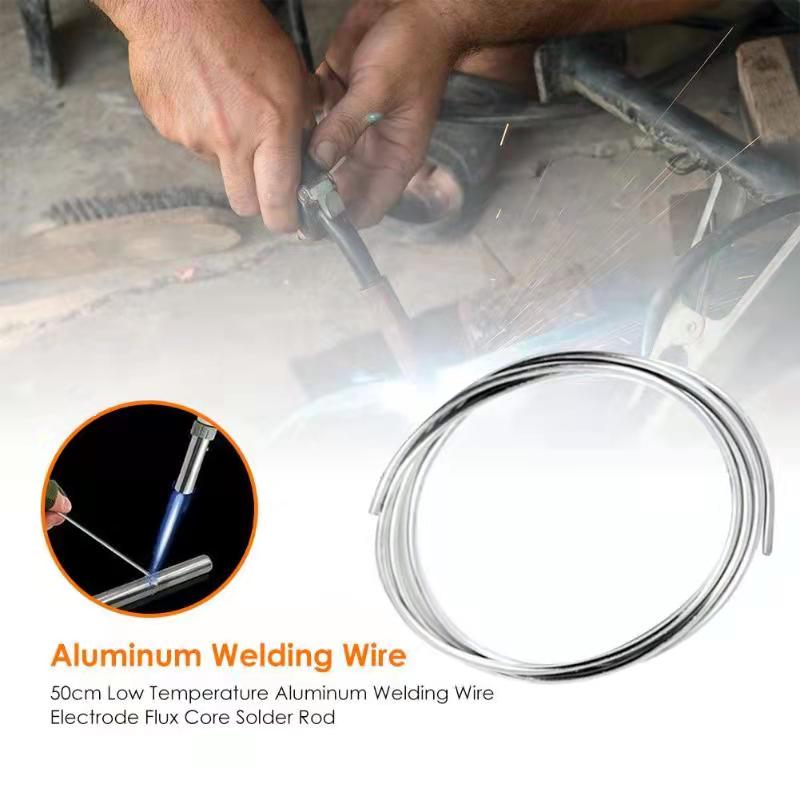

【 Cored wire and solid wire use 】

1, cored wire is mainly used for flat welding and fillet welding, used for welding construction machinery, heavy machinery, steel frame, bridge, etc.

2, solid welding wire is widely used in welding work, is used as a filler metal or at the same time as a conductive metal wire welding material. In gas welding and TUNGSTEN gas shielded arc welding, welding wire is widely used as filler metal. In submerged arc welding, electroslag welding and other gas shielded arc welding, welding wire is both filler metal and conductive electrode. The specific selection depends on the raw materials needed for welding.

www.chingray.com

www.chingray.com