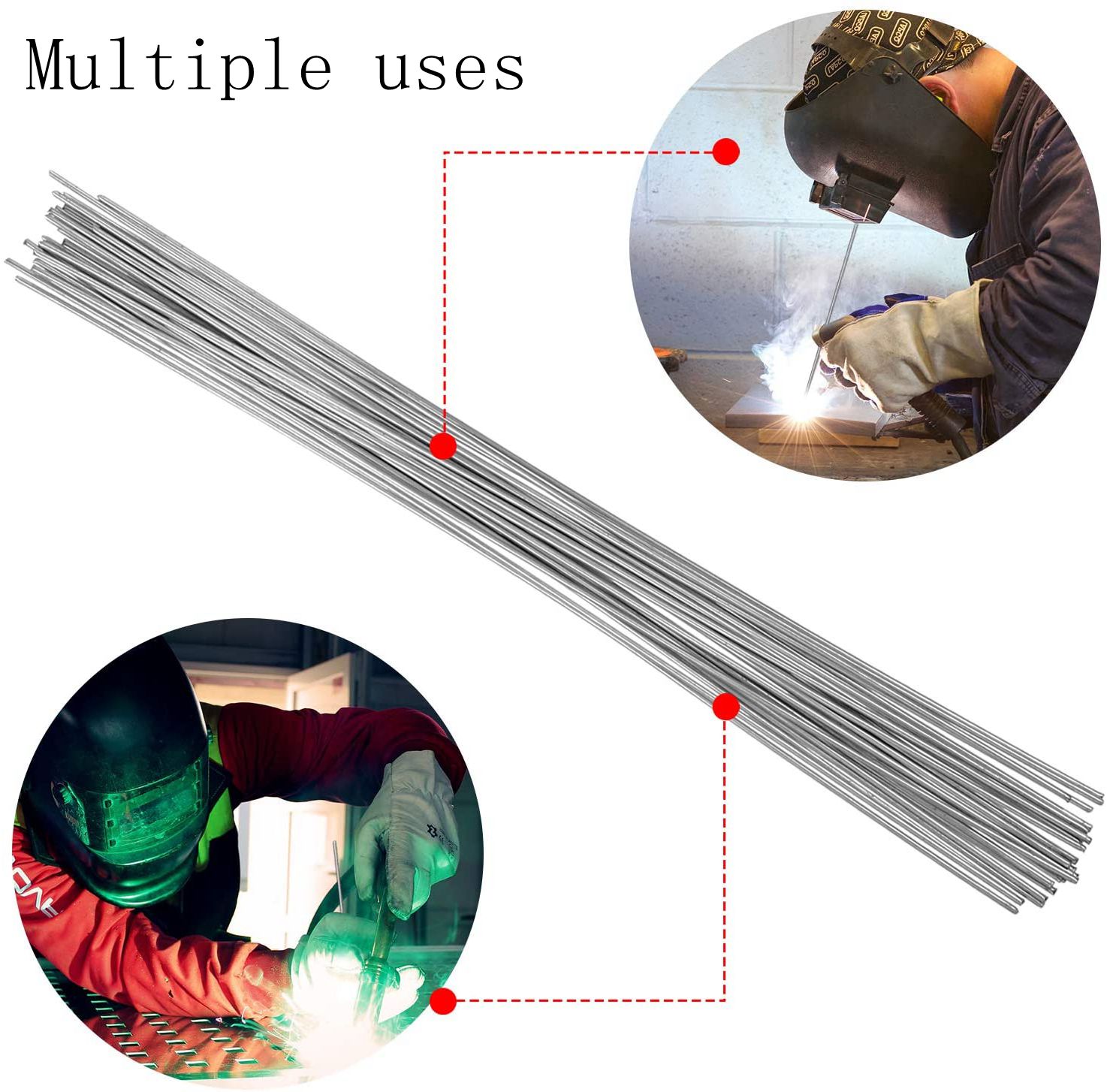

Flux-cored wire, also known as tubular wire, can be adjusted by adjusting the type and proportion of flux-cored additives, it is very convenient to design a variety of welding materials for different purposes, because its alloy composition can be flexible and convenient adjustment, so many varieties of flux-cored wire is solid wire can not smelting and rolling.

Gas shielded flux cored wires were first developed in the early 1950s, but were not commercially available until 1957. This method can be said to be derived from the advantages of submerged arc welding and CO2 welding (solid), flux wrapped in the wire and with the protection of CO2 gas can produce a soft and stable welding arc and low splash for its characteristics. At the beginning of development, only large wire diameter welding wire (2.0-4.0mm), used for heavy workpiece welding and horizontal welding. It was not until 1972 that the development of small wire diameter welding wire greatly expanded the field of flux cored wire.

Self-protected flux cored wire is not long after the gas shielded flux cored wire market was developed and is quickly widely recognized in the industry for specific purposes.

Flux cored wire is a new welding material developed rapidly in recent years and has been widely used in industrialized countries. According to the information: Japan from 1985 to now its welding rod accounted for the proportion of the whole welding material decreased from 45% to 20%; The proportion of flux cored wire has reached nearly 30%. In the United States, the percentage of electrodes has dropped to less than 40 percent, and flux-cored wire to nearly 40 percent; Western European welding treaties account for 30%, flux-cored wire about 20%. It can be seen that in the past decade, the proportion of traditional electrodes in industrialized countries is declining, while the proportion of flux-cored wires in the whole welding material is greatly increased.

Compared with manual electrode and argon arc welding wire, flux cored wire has obvious advantages, which mainly changes the discontinuous welding process into continuous production mode, thus reducing the number of welded joints, improving the quality of welding seam, improving the production efficiency and saving energy.

Flux-cored wire, also known as tubular wire, can be adjusted by adjusting the type and proportion of flux-cored additives, it is very convenient to design a variety of welding materials for different purposes, because its alloy composition can be flexible and convenient adjustment, so many varieties of flux-cored wire is solid wire can not smelting and rolling.

Flux-cored wire is divided into stitched and seamless flux-cored wire, seamless flux-cored wire finished wire can be copper plated, wire storage in the process of moisture resistance and welding conductivity are better than stitched flux-cored wire.