Product Specification

Material: aluminum

Color: silver

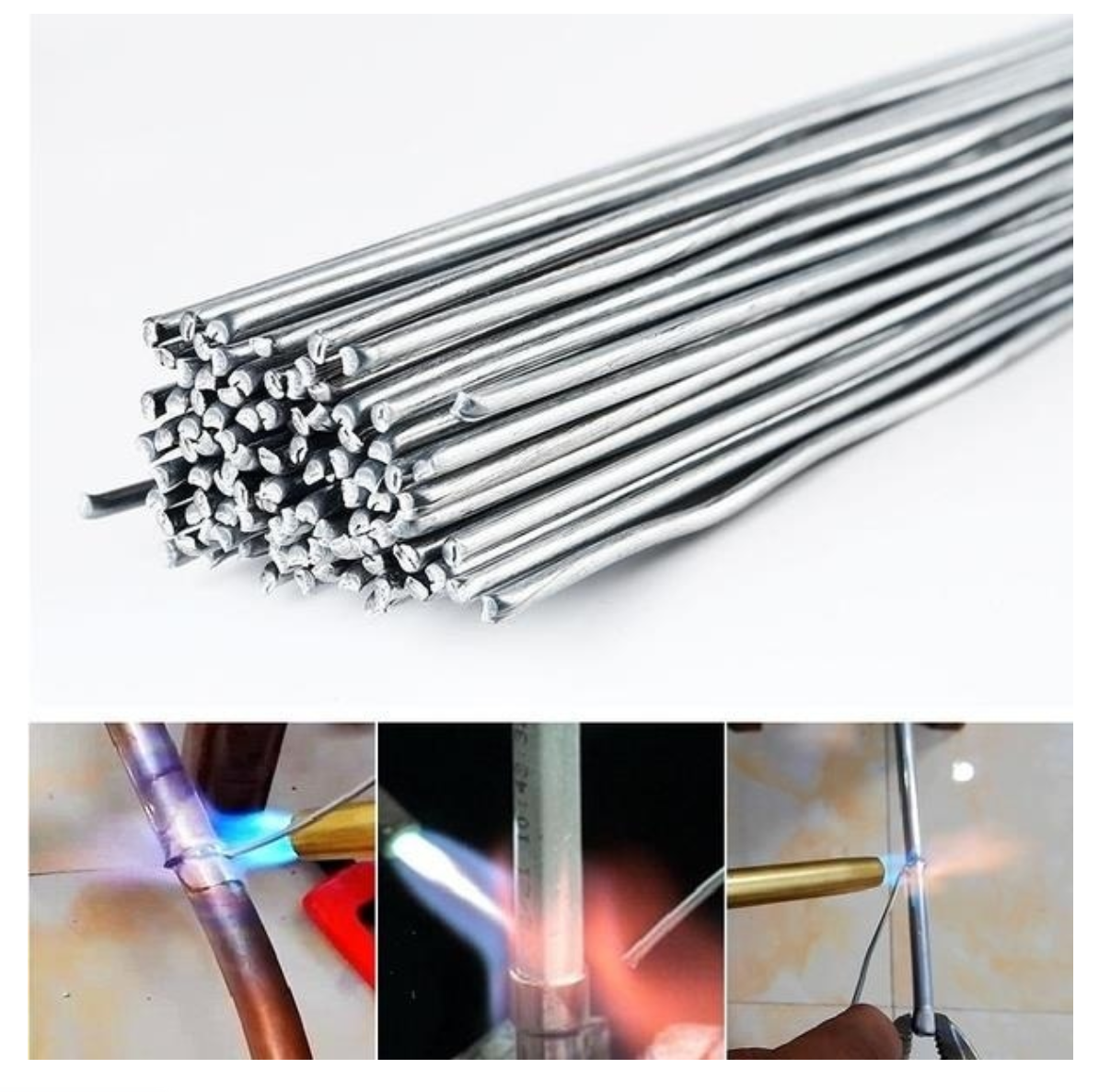

Operating Temperature: 380-450°

Diameter: 2mm / 0.08", 1.6mm/ 0.06"

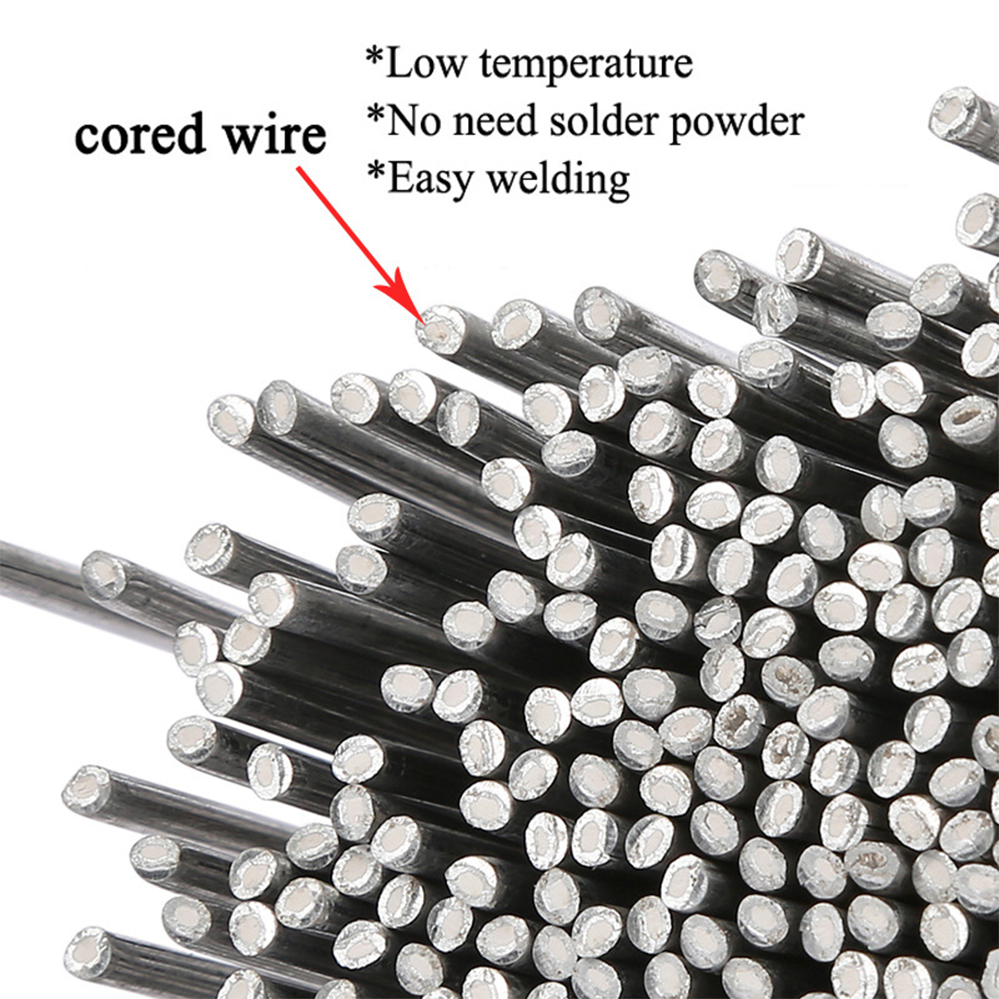

Aluminum flux cored wire is a solder with brazing agent without soldering powder. Its outer skin is aluminum silicon alloy and its inner layer is a composite brazing material composed of white fluoride brazing agent. White brazing agent is non-hygroscopic, non-corrosive, no need to clean after welding. The products are suitable for flame brazing, induction brazing and furnace brazing of all aluminum heat exchangers for refrigeration and air conditioning, refrigerator, automobile air conditioning, heat pump, cold storage aluminum row, all kinds of aluminum pipes, aluminum connecting parts and so on.

Features:

1. Widely use-- suitable for welding or surfacing welding alloy with high strength, good forgeability & good corrosion resistance.

2. Good quality material-- made of aluminum material, nontoxic, odourless and durable material.

3. No solder powder needed-- there is no need to use other flux powder with aluminum alloy as the welding core and coating as the salt base.

4. Application-- include welding filler wire and spray and flame metalizing wire. It also used for argon arc welding and filling material for pure aluminum, connection with aluminium bus and guide rod of electrolytic aluminium plant and electric power, chemistry, food and so on.

5. Perfect welding effect-- designed with full & smooth welding effect because the item comes with internal powder, great weldability and corrosion resistance, high thermal conductivity, high electric conductivity and excellent processing performance.

Product advantages:

Easy to use, with brazing agent, low welding temperature, excellent fluidity;Strong gap filling ability, excellent crack resistance and high tensile strength;Seamless design, strong air tightness, reduce powder loss

Application areas:

Electrical, refrigeration, hardware, raw aluminum and aluminum alloy, aluminum and copper parts welding.